Why Plastics for the Oil and Gas Industry?

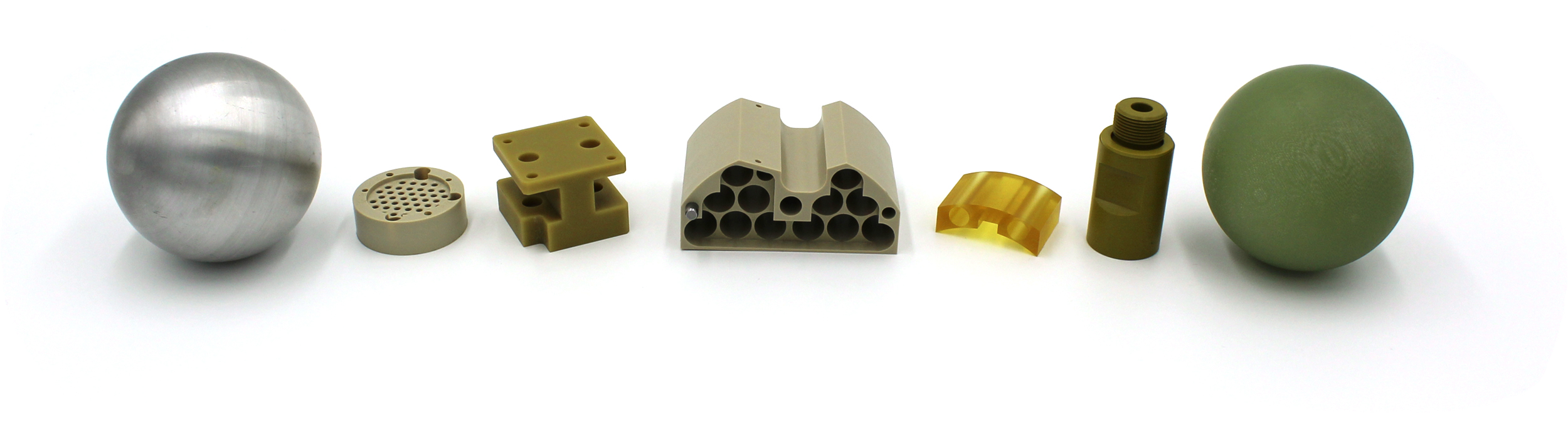

Plastics and composites offer significant advantages in the most challenging oil & gas applications over traditional materials like metal, offering significant weight savings, improved chemical and corrosion resistance, thermal and electrical insulation, reduced friction, enhanced wear resistance, cryogenic to 600+F temperature range, along with many other advantages.

Plastics have a long history of service in onshore, downhole, offshore and subsea applications providing longer part life and greater reliability with their enhanced properties in electrical component, bushing and bearing, seal, structural components and other applications. As the industry has evolved with unconventional production methods like hydraulic fracturing and deeper wells that require HPHT (higher pressure higher temperature), newer materials have been developed for these unique requirements.

Why Boedeker Plastics, Inc. for the Oil and Gas Industry?

Since 1984, Boedeker Plastics, Inc. has worked closely with R&D, Engineering, Supply Chain and other personnel in all segments of the Oil & Gas Industry to solve challenging applications and supply demands with our services, materials & products. Over the years we have seen many advancements in equipment design and materials as the oil & gas industry has evolved with improved exploration and production processes.

In many of those processes high performance plastics and composite materials and parts have been incorporated for improved reliability and longer service life. Over the years, we have built a multimillion dollar inventory of high performance plastic and composite sheet, rod and tube and an ISO certified precision machine shop to support our clients with the most challenging requirements. In addition, we offer injection molding for higher part volume requirements. All inventoried materials are available with cut to size and same day shipping service. For clients that have ongoing part requirements we offer just-in-time (JIT) delivery with our customer inventory services.

We also specialize in technical services that include materials selection by application, improved part design assistance, onsite consultation and more. We stand ready to put our 1,800 years of combined experience and services to work for you.

As an alternative to onsite consultation we offer our TelePlastics™ remote support service. This is a safe and secure remote solution, for the diagnosis and recommendation of plastic solutions, by our experienced Technical Service staff, utilizing the latest in telecommunication technology.

Click Here to view ALL Oil & GAS Industry Plastics & Composites

![]()