Why Plastics for Surgical Robotic Systems?

Plastics are used extensively in a wide variety of Surgical Robotic Systems and chosen often to replace traditional materials like aluminum and metal in these applications with the many benefits they offer, from chemical resistance and weight reduction, enhanced wear resistance on wear components, to (in many cases) FDA and USP Class VI compliance as well as cost reduction opportunities via material pricing and for high volume applications with lower part costs utilizing injection molding manufacturing processes.

Surgical Robotic Plastic Applications

Some of the key applications include housings and other structural components along with rotating and linear wear components. The video below shows a surgical robot system that utilizes a wide range of plastics for structural and bearing and wear applications. Note: the external white plastic housings on the robots arms and black wear components on the telescopic arm assembly.

Surgical Robotic Control Station Plastic Components

The below surgeon control station utilizes Polycarbonate, Ultem™, PEEK and Radel® molded plastics for the external housing covers, instrumentation and electrical components. The benefits of plastics in these applications include impact strength, chemical resistance, electrically insulating properties and more.

Surgical Robotic End Effector Plastic Components

In the below photo an end effector is highlighted, which utilizes plastic materials including bearing grade PEEK internally for critical wear components and blue injection molded thermoplastic elastomer for gripping pads. The end effector pictured is just one of many types of end effectors. End effectors are designed in many different configurations to perform gripping, cutting, probing and other operations. Plastics are used in these applications for bio-compatibility, chemical resistance, wear resistance for wear components, dimensional stability and weight reduction.

![]()

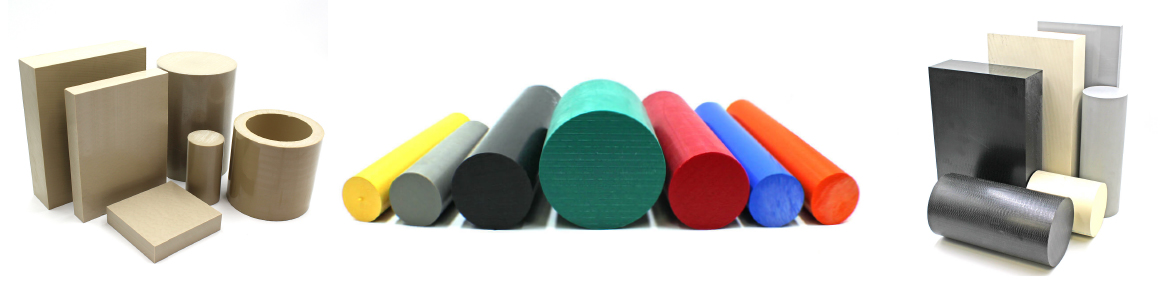

Since 1984 we have specialized in the Medical Industry and stock a wide range of commercially available Medical Grade plastics with cut to size and same day shipping on all inventoried Medical Grade plastics. Our entire inventory of plastics & composites are coded for full traceability, we offer manufacturer certs. and C of C’s upon request at the time of order for all orders.

State of the Art Manufacturing

We specialize in plastics-only machining and produce CNC machined parts in prototype to production quantities. Our facility is ISO 9001 & 13485 certified, we also offer injection molding services for higher part volumes which are common with surgical robotic systems backed by our inhouse mold flow analysis and tool design services. For customers that have specific validation or qualification requirements we offer a full range of qualification and validation services.

We offer technical support for Medical Applications regarding material selection by application, part design assistance & machining support.

As an alternative to onsite consultation we offer our TelePlastics™ remote support service. This is a safe and secure remote solution, for the diagnosis and recommendation of plastic solutions, by our experienced Technical Service staff, utilizing the latest in telecommunication technology.

Just in Time (JIT) Shipments | Greatly Reduce Inventory Costs

To meet the challenging demands of reducing inventory and associated costs in carrying large part inventories in manufacturing Boedeker Plastics, Inc. offers

JIT supply, with our state of the art climate controlled part inventory facility. This greatly reduces our customers' on-hand part inventory and associated costs with carrying large part inventories, providing our clients with parts just in time to support their manufacturing requirements as needed.

![]()