Delrin® ACETAL POM Key Properties

Delrin® acetal homopolymer offers slightly higher mechanical properties than acetal copolymer, but may contain a low density center (also known as "center line porosity") especially in large cross-sections. The homopolymer also gives slightly less chemical resistance than copolymer acetal. For example, Delrin® is ideal for small diameter, thin-walled bushings that benefit from the additional strength and rigidity of homopolymer acetal.

- Excellent Dimensional Stability

| | - Higher Strength & Stiffness than Copolymer Acetal

|

- Low Coefficient of Friction

| | - Wear Resistance in Wet Environments

|

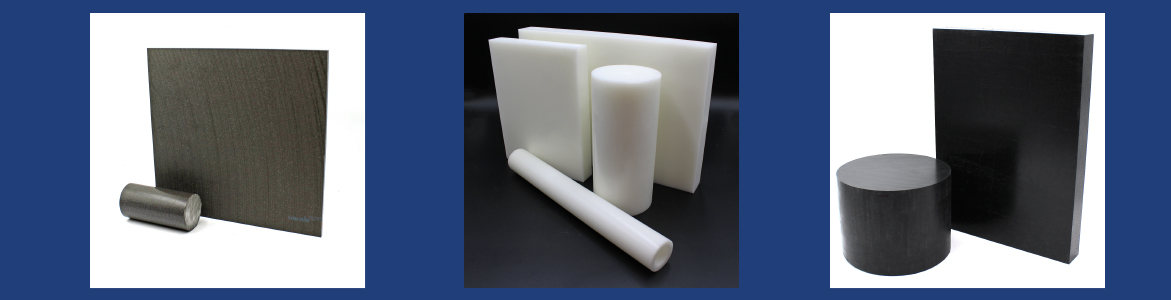

Common Delrin® Acetal POM-H Grades We Stock

Common Delrin® Acetal POM-H Grades We Stock

Delrin®

Grade | Description | ASTM

Resin Specification | ASTM

Shape Specification |

| - Natural

Unfilled Delrin POM-H Acetal

| | |

| - Black

Unfilled Delrin POM-H Acetal

| | |

| - 13%

PTFE Filled Delrin 100 - the most common AF grade

| | |

| - 13%

PTFE Filled Delrin 500

| | |

| - 20%

PTFE Filled Delrin 100 or 500

| | |

| - 20%

PTFE Filled DE588 - Naval Grade

| | |

| - Higher

crystallization Delrin POM-H Acetal grade

| | |

| - UV Resistant Delrin POM-H Acetal grade

| - ASTM D6778-20 POM0132 (ASTM D4181 withdrawn 2005, Replaced by D6778)

| - ASTM D6100-17 S-POM01601222434(Only for Acetal shapes >0.062" thick)

|

| - 20% glass filled Delrin POM-H Acetal Grade

| | |

What is the difference between Delrin®, Acetal Homopolymer & Acetal Copolymer? Check out our Understanding Acetals Guide to find out.

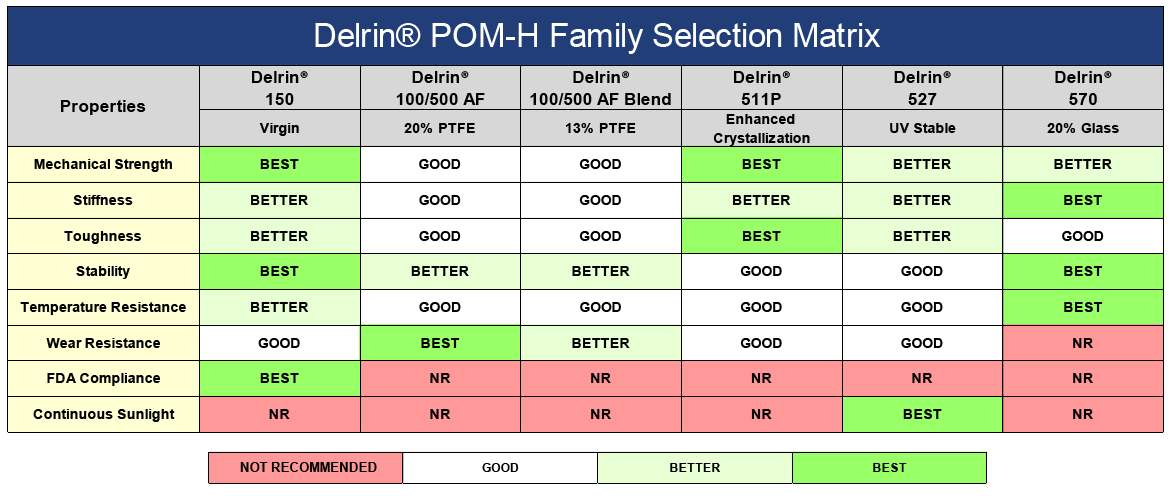

What Delrin® Grade is best for your applications? Use our Delrin® Selection Matrix to narrow down your choices.

![]()

Boedeker Plastics, Inc. & Delrin® ACETAL POM

We stock a wide range of commercially available Delrin® grades in sheet,

rod & tube and offer cut to size, same day shipping on all inventoried Delrin® materials. Our

entire inventory of Delrin® is coded for full traceability, we offer manufacturer certs. and C of C’s

upon request at the time of order for all orders.

We specialize in plastics-only machining and produce CNC machined Delrin® parts for prototype to production

quantities. We offer technical support with Delrin® materials & parts

regarding material selection by application, part design assistance & machining support.

In addition, we offer injection molding for of Delrin® grades for higher part volume requirements in a wide range of applications. For clients that have ongoing part requirements, we offer just-in-time (JIT) delivery with our customer inventory services.

In addition, we offer injection molding for of Delrin® grades for higher part volume requirements in a wide range of applications. For clients that have ongoing part requirements, we offer just-in-time (JIT) delivery with our customer inventory services.

We also specialize in technical services for Delrin® materials and parts that include material selection by application, improved part design assistance, onsite consultation and more.

As an alternative to onsite consultation we offer our TelePlastics™ remote support service. This is a safe and secure remote solution, for the diagnosis and recommendation of plastic solutions, by our experienced Technical Service staff, utilizing the latest in telecommunication technology.

We stand ready to put our 1,800 years of combined experience and services to work for you.

![]()