Quality Policy

Boedeker Plastics, Inc. is a World-Class distributor of industrial and engineering plastic stock shapes and manufacturer of high performance CNC machined plastic components.

We are committed to Quality and to operating a Quality Management System that will enable us to develop and maintain a culture that is self-critical, honest and transparent. We are committed to maintaining a Quality Management System that enables us to evaluate our strengths and weaknesses and respond to improvement needs effectively.

All employees share responsibility for implementation, documentation and continuous improvement of our Quality Management System, its procedures and Quality Objectives. All employees participate in technical and Quality System training as part of our ongoing continuous improvement process.

It is our desire to clearly understand the current and future requirements of our customers both existing and potential, along with their expectations of us as an approved supplier. We have established measurable customer satisfaction objectives that must be met and/or exceeded by all employees throughout the order and production processes.

We work closely with our suppliers to insure that we consistently receive products and services of the highest quality and reliability. Our management team and all the employees of Boedeker Plastics, Inc. are committed to continually review and improve on our manufacturing processes, our Quality Objectives and levels of service; such that our Customers are always aware of our ongoing commitment to business excellence.

With this Policy, planned and developed jointly with all our management functions, we are committed to operating our Company under the disciplines and control of Quality Management Systems conforming to the International Standards ISO 9001:2015, ISO 13485:2016, and all applicable State & Federal Regulations.

This policy is approved by the undersigned and is supported by all levels of management within this organization. All personnel shall be guided by the contents of the Quality Management System and no deviation from the methods and procedures set down shall be permitted.

Marvin Boedeker

President

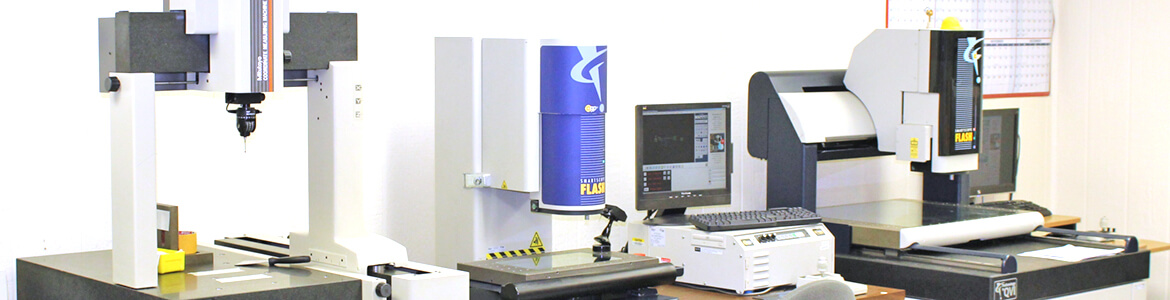

Metrology Equipment List

Carl Zeiss CONTURA G2 CMM (3)

CALYPSO metrology software with

3D curve and freeform

Keyence IM-6120 Image Dimension Measuring

Mitutoyo BH 305 Manual Floating Type CMM

Mitutoyo Surftest 211

Mitutoyo Surftest SJ-400

SmartScope Flash 250 (2)

SmartScope Flash 500

Vision Engineering 5E Inspection System

At Boedeker Plastics, Inc. we utilize a wide variety of qualifications and validations during different stages of production. The three main stages include IQ (Installation Qualification), OQ (Operational Qualification), PQ (Process Qualification). Other types of qualifications and validations we perform include; Process Flow Plan, pFMEA (Process Failure Mode Effects Analysis), Control Plan, Process Materials Contact List, RoHS, REACh, Animal Derivatives and Gage Certifications.

For clients with unique validation requirements we offer a customizable Full Process Design Qualification and Validation Services with options for their specific requirements. This service is available to our customers and is based on their unique requirements, additional costs vary depending on the customers’ unique qualification and validation requirements. This typically involves a validation plan, programming for CNC and quality equipment, initial dimensional and visual checks, and any documentation such as pFEMA, REACh, etc. needed.

Learn More About Our Qualification & Validation Services