Why Radel® & Heat Stabilized Polypro for Hip, Knee & Shoulder Orthopedic Sizing Trials?

Orthopedic sizing trials require materials that can handle repeated steam sterilization cycles, biocompatibility, and excellent dimensional stability.

Two materials that fit these parameters include Radel® R5500 PPSU Polyphenylsulfone & Propylux® HS Heat Stabilized Polypropylene; Radel® has become the industry standard for orthopedic sizing trials, with Propylux® HS becoming a popular alternative. In addition to both materials handling repeated sterilization, they are also FDA, USP Class VI & ISO 10993-5 compliant and offer excellent dimensional stability. Radel® & Propylux® are available in a wide range of standardized commercially available colors.

Common Medical Grade Plastics used in Orthopedic Applications by Sterilization Method

Radel® is excellent for the five most common sterilization methods: Ethyle Oxide Gas (ETO), Steam, Dry Heat, Plasma & Gamma Radiation, which is the best out of the most commonly used orthopedic sizing trial plastics. Propylux® HS is excellent for ETO & Steam and good for Plasma. Below is a chart showing four common medical-grade plastics used in orthopedic applications by sterilization method.

| Material | Ethylene Oxide Gas / ETO | Steam 121 C / 134 C | Dry Heat 160 C | Plasma | Gamma Radiation |

| PPSU - Radel® | Excellent | Excellent | Excellent | Excellent | Excellent |

| PEI - Ultem™ | Good | Good | Excellent | Good | Good |

| Acetal POM-C | Good | Poor | Not Suited | Good | Good |

| PolyPro Heat Stabilized - Tecapro MT - Propylux® HS | Excellent | Excellent | Not Suited | Good | Poor / Not Suited |

![]()

Why Boedeker Plastics, Inc. for Hip, Knee & Shoulder Orthopedic Sizing Trials?

Unmatched Medical Grade Plastics Inventory the Boedeker Way

Since 1984 we have specialized in the Medical Industry and stock a wide range of commercially available Radel® and Heat Stabilized Polypro rods for orthopedic sizing trials and an unmatched inventory of medical grade plastics and offer cut to size, same-day shipping on all inventoried Medical Grade plastics & composites.

Our entire inventory of plastics & composites is coded for full traceability; we offer manufacturer certs. and C of C’s upon request at the time of order for all orders.

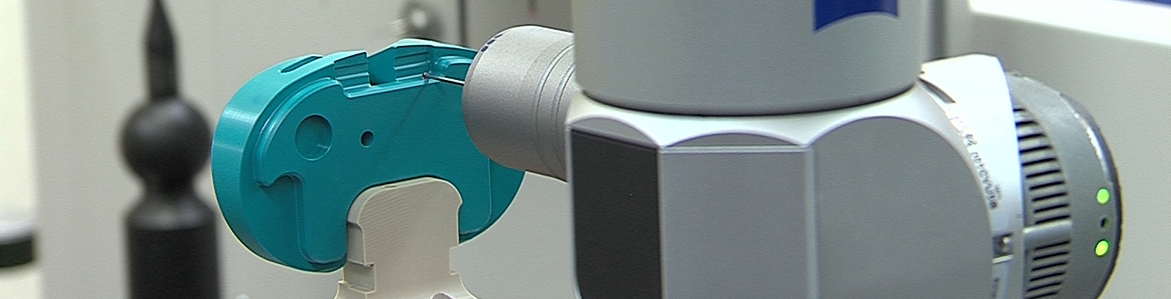

State of the Art Manufacturing the Boedeker Way

We specialize in plastics-only machining and produce CNC machined orthopedic sizing trials in prototype to production quantities. Our facility is ISO 9001 & 13485 certified, and we utilize the latest cryogenic deburr technology, UDI laser marking, and laser marking systems in our manufacturing processes. In addition, we offer injection molding services for higher part volumes.

We offer a full range of qualification and validation services for customers with specific validation or qualification requirements. We provide technical support for Medical Applications regarding material selection by application, part design assistance & machining support.

Just in Time (JIT) Shipments | Greatly Reduce Inventory Costs the Boedeker Way

To meet the challenging demands of reducing inventory and associated costs in carrying extensive part inventories in manufacturing, Boedeker Plastics, Inc. offers JIT supply with our state-of-the-art climate-controlled part inventory facility. JIT supply dramatically reduces our customer’s on-hand part inventory and associated costs with carrying extensive part inventories, providing our clients with parts just in time to support their manufacturing needs as needed.

Expert Technical Support the Boedeker Way

We offer onsite consultation, and as an alternative to onsite consultation, we offer our TelePlastics™ remote support service. TelePlastics™ is a safe and secure remote solution, for the diagnosis and recommendation of plastic solutions, by our experienced Technical Service staff, utilizing the latest telecommunication technology.

![]()