Engineering Services

We offer a variety of services to assist our customers with material selection and design to help maximize part performance when using plastics and composites.

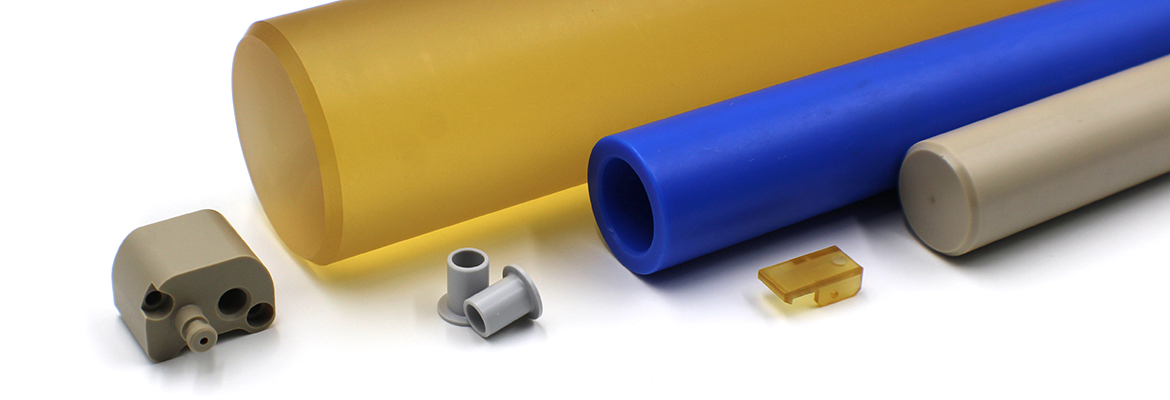

Material Selection by Application

With over 500 years of combined plastics and application experience we can help in assessing all application parameters to help select the best plastic or composite material candidates for testing in your application. In addition, we have a dedicated Outside Staff of Technical Services & Application and Industry Specialists located throughout the United States that can assist clients with onsite consultation to help solve challenging problems with plastics and composites. In many cases plastics and composites are ideal choices for metal replacement or upgrading the existing plastic or composite for enhanced part performance and extended part life in process.

Use our Plastics Selection Tool to narrow down material choices by your application parameters.

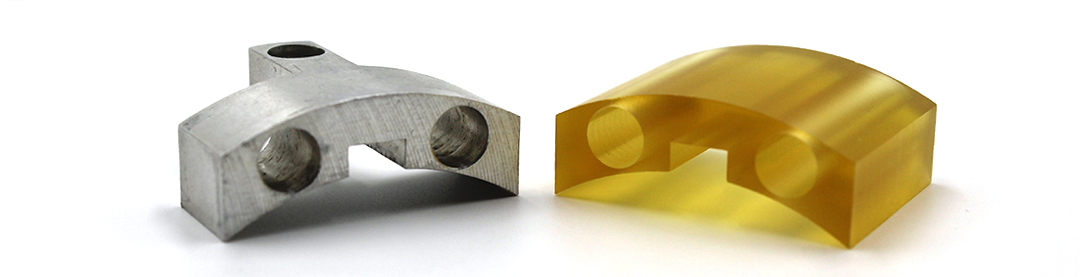

Part Design Assistance

We assist customers with part design to ensure realistic tolerances and the correct geometries are considered when designing with plastics or composites, to eliminate excessive manufacturing cost or potential issues with failure when the part is machined or molded during production or in the field.

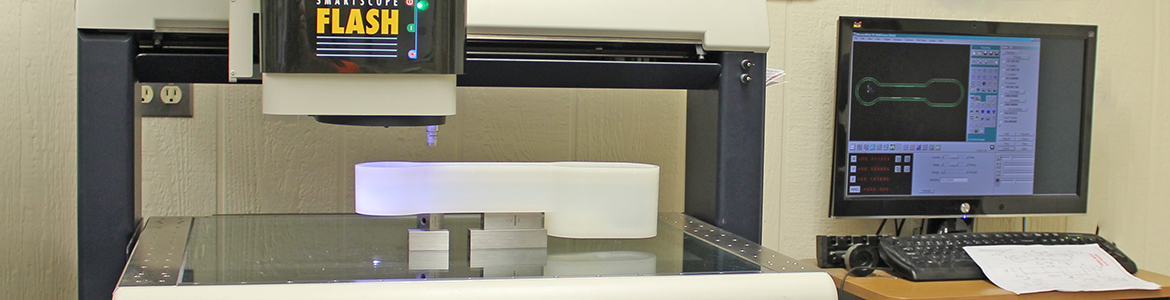

Reverse Engineering

With our Metrology lab and skilled personnel, we have a variety of machines and software that are used to create 3D models and prints to your part. Our process involves working with our customers to understand the function of the part to help ensure nominal feature size interpretation and proper tolerances are utilized. We can identify the current material and after review of all the application parameters assist with material selection and recommend material options for testing for enhanced performance.

Value Engineering

We work closely with our customers to control part cost and evaluate alternative manufacturing processes as the part transitions from prototyping to machining to injection molding. In some cases, it is possible to streamline part design and eliminate features that create additional un-needed cost in manufacturing.

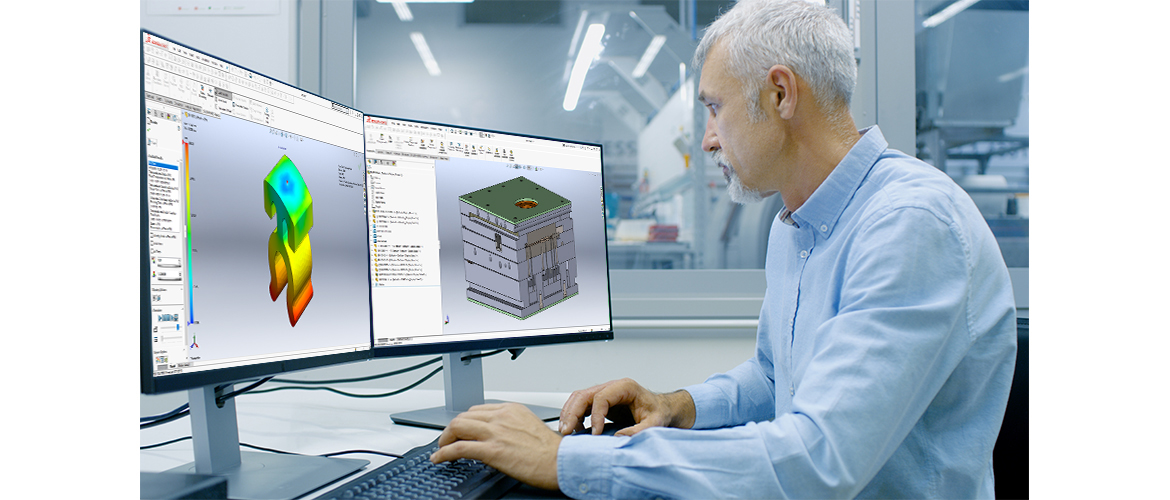

Mold Flow Analysis

We do Injection Molding the Boedeker Way with a complete injection molding solution that includes Mold Flow Analysis services. Our MFA services are performed by our injection molding engineer who has decades of experience with injection molded plastic part design, injection mold design and mold making. MFA services are available to all Boedeker Plastics, Inc. injection molding clients as part of our complete injection molding solution and not as a standalone service. Go to our Mold Flow Analysis page for information on our MFA services.