What are Common Electrical Connectors & Housings Materials?

Electrical connectors require electrically conductive materials, like copper alloys, beryllium copper, and other metals often coated with gold, nickel, and tin to conduct electricity. They also need electrical insulative materials to contain electricity with high dielectric strength, good dimensional stability and handle a wide range of temperatures and other requirements depending on the application. Plastics, composites, ceramics, and glass are all common materials used for the insulative components for electrical connectors and housings.

Why Plastics & Composites for Electrical Connectors & Housings?

Plastics & composites are ideal for insulative components for housings and electrical connector applications through their ease of manufacturing. Plastics and composites offer various options for cost-effective processes that include high volume machining and a variety of injection molding options that include insert and over-molding.

Depending on the electrical connector or housing application, there is a wide range of plastics & composites to choose from that are electrically insulative and offer excellent dimensional stability, high dielectric strength, UL 94 5V or V-0 flammability.

Common Plastics & Composites Properties for Electrical Applications Sorted by Dielectric Strength

| Material | Dielectric Strength | Max Operating Temp. | CLTE | Flammability | Tensile Strength |

| CPVC Corzan ® Gray | 1,250 V/mil | 93 °C / 200 °F | 3.7 x 10^-5 in./in./°F

| UL94 V-0

| 8,200 psi |

| G-11 FR-5 Glass Epoxy Laminate | 900 V/mil | 180 °C / 356 °F | 0.55 x 10^-5 in./in./°F

| UL94 V-0 | 43,000 psi |

| ULTEM ™ 1000 Natural Unfilled PEI | 830 V/mil | 171 °C / 340 °F | 3.1 x 10^-5 in./in./°F

| UL94 V-0 | 16,500 psi

|

| G-10 FR-4 Glass Epoxy Laminate | 800 V/mil | 140 °C / 284 °F

| 0.55 x10^-5 in./in./°F | UL94 V-0 | 45,000 psi |

| ULTEM ™ 2300 30% Glass Filled PEI | 770 V/mil

| 171 °C / 340 °F

| 1.1 x 10^-5 in./in./°F

| UL94 V-0 | 17,000 psi |

| Nylatron 4.6 | 635 V/mil | 149 °C / 300 °F

| 5.0 x 10^-5 in./in./°F

| UL94 HB | 15,000 psi |

Phenolic LE Linen Laminate

| 625 V/mil

| 125 °C / 257 °F

| 1.8 x 10^-5 in./in./°F

| UL94 HB | 13,000 psi |

PEEK HT High Temperature

| 584 V/mil

| 249 °C / 480 °F

| 2.2 x 10^-5 in./in./°F

| UL94 V-0 | 16,500 psi |

| Celazole ® U-60 Unfilled PBI | 580 V/mil | 343 °C / 650 °F

| 1.3 x 10^-5 in./in./°F

| UL94 V-0 | 23,000 psi

|

| Torlon ® 4203 Electrical Grade PAI | 580 V/mil | 260 °C / 500 °F

| 1.7 x 10^-5 in./in./°F | UL94 V-0 | 18,000 psi |

| Vespel ® Polyimide SP-1 Unfilled | 560 V/mil | 260 °C / 500 °F | 3.0 x 10^-5 in./in./°F

| UL94 V-0 | 12,500 psi |

| Phenolic CE Canvas Laminate | 550 V/mil | 125 °C / 257 °F

| 2.0 x 10^-5 in./in./°F | UL94 HB | 10,000 psi

|

PVC Gray Type I

| 544 V/mil | 60 °C / 140 °F

| 6.1 x 10^-5 in./in./°F | UL94 V-0 | 7,500 psi

|

PPS Unfilled Virgin

| 540 V/mil | 218 °C / 540 °F

| 2.8 x 10^-5 in./in./°F | UL94 V-0 | 13,500 psi

|

Noryl ® 30% Glass Filled PPO

| 530 V/mil | 104 °C / 220 °F

| 1.4 x 10^-5 in./in./°F | UL94 V-0 | 17,800 psi

|

PEEK GF30 - 30% Glass Filled

| 500 V/mil | 249 °C / 480 °F

| 1.2 x 10^-5 in./in./°F | UL94 V-0 | 15,000 psi

|

Noryl ® Unfilled PPO

| 500 V/mil | 104 °C / 220 °F

| 3.3 x 10^-5 in./in./°F | UL94 V-0 | 9,600 psi

|

PEEK Unfilled Virgin Natural

| 480 V/mil | 249 °C / 480 °F

| 2.6 x 10^-5 in./in./°F | UL94 V-0 | 16,000 psi

|

Sustakon ® PK Polyketone

| 480 V/mil | 120 °C / 248 °F

| 6.1 x 10^-5 in./in./°F | UL94 HB

| 8,818 psi

|

GPO-3 Glass Polyester Laminate

| 450 V/mil | 160 °C / 320 °F

| 2.0 x 10^-5 in./in./°F | UL94 V-0 | 9,000 psi

|

Nylon Type 6/6

| 400 V/mil | 99 °C / 210 °F

| 5.5 x 10^-5 in./in./°F | UL94 V-2

| 12,000 psi

|

![]()

Why Plastics & Composites the Boedeker Way for Electrical Connectors & Housings?

We have you covered from material to finished machined or molded parts and everything in between. We specialize in plastics and composites and stand ready to assist with an unmatched inventory of sheet, rod, or tube, CNC machined, injection molded parts, JIT supply, and technical services.

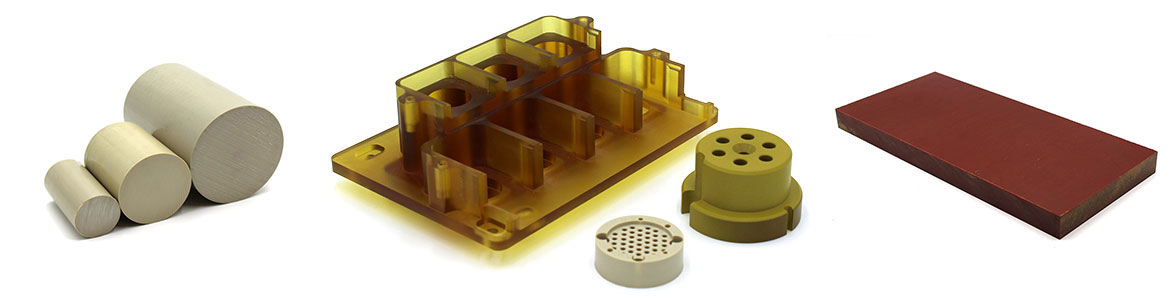

Plastics & Composites Sheet, Rod & Tube Inventory

We stock all commercially available grades of plastic and composite materials for electrical connector and housing applications in sheet, rod, and tube and offer cut to size, same-day shipping on all inventoried plastic and composite materials. Our entire inventory of plastics and composites are coded for full traceability; we offer manufacturer certs. and C of C’s upon request at the time of order for all orders.

ISO Certified CNC Plastics & Composites Only CNC Machining

We specialize in ISO-certified CNC machining of plastic and composite electrical connectors and housings and produce CNC machined parts in prototype to production quantities.

ISO Certified Injection Molding

In addition, we offer injection molding for higher part volume requirements, including over-molded and insert-molded electrical connectors.

Supply Services & Technical Support

For clients that have ongoing part requirements, we offer just-in-time (JIT) delivery with our customer inventory services.

We also specialize in technical services for electrical connectors and housing plastics and composite materials and parts, including selection by application, improved part design assistance, onsite consultation, and more. We stand ready to put our 1,800 years of combined experience and services to work for you.

As an alternative to onsite consultation, we offer our TelePlastics™ remote support service. This is a safe and secure remote solution, for the diagnosis and recommendation of plastic solutions, by our experienced Technical Service staff, utilizing the latest in telecommunication technology.

![]()