Why Plastics for Scraper Blades / Mixing Paddles?

Plastics Maximize Wear Life & Reduce Downtime

Depending on the temperature requirements, ingredients being mixed, caustic washdown exposure and other factors of the mixer application, there is a plastic material that can fit those requirements and maximize wear life and minimize downtime. Some of the most common plastic materials for scraper blade and mixing paddles include but are not limited to UHMW-PE, Delrin POM Acetal, Nylon PA, PVDF and PEEK.

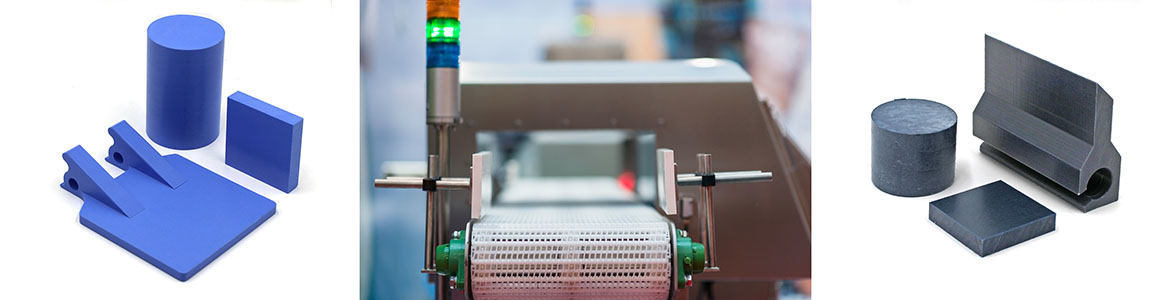

Detectable Plastics Enhance Food & Product Safety

Scraper blades and mixing paddles can fragment and wear over time making them a perfect fit for a detectable plastic. For applications where customers utilize metal or x-ray detection there are both metal and x-ray detectable grades of plastics for scraper blades / mixing paddles and other food contact critical parts. When a detectable plastic is combined with detection equipment food or product safety are enhanced, minimizing the chance for a fragment of plastic from the scraper or blade to go un-detected and making it to the consumer. Using detection equipment and detectable plastics can greatly reduce recalls due to foreign contamination and the resulting financial loss and damage to brand reputation caused by recalls.

How Detectable are Metal & X-Ray Detectable Plastics? Watch our detectable video and download our free whitepaper and learn more about detectable plastics.

![]()

Why Boedeker Plastics, Inc. for Scraper Blades / Mixing Paddles?

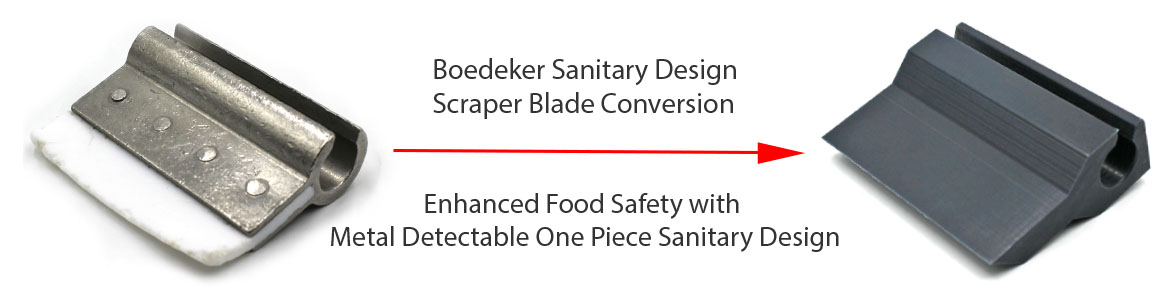

We enhance food safety and reduce downtime with higher performance plastics, detectable plastics and can assist with sanitary design and other design enhancements for improved performance - Learn More and Download our Sanitary Design Case History.

We specialize in Food, Pharmaceutical and other industries and have extensive experience with a wide range of mixer, blending and kettle cooking applications. We offer a complete plastic solution with Plastics the Boedeker Way.

Inventory & Service the Boedeker Way

Over the years, we have built a multimillion dollar inventory which includes a wide range of commercially available FDA compliant plastic sheet, rod and tube, and metal & x-ray detectable plastics along with enhanced grades that offer extended wear life.

Our entire inventory is coded for full traceability to give our customers peace of mind that they have received what they ordered.

All inventoried materials are available with cut to size and same day shipping service. For clients that have ongoing part requirements, we offer just-in-time (JIT) delivery with our customer inventory services.

Scraper Blade & Mixing Paddle Manufacturing the Boedeker Way

We offer machined scraper blades and mixing paddles with our ISO certified precision machining to support our clients with the most challenging requirements for plastics only machined plastic and composite parts.

In addition, we offer injection molding for higher scraper blade or mixing paddle volume requirements in applications that require additional cost reduction over machined parts.

Technical Support the Boedeker Way

We also specialize in technical services that include material selection by application, improved part design assistance, reverse engineering, onsite consultation and more. We stand ready to put our 1,800 years of combined experience and services to work for you.

As an alternative to onsite consultation we offer our TelePlastics™ remote support service. This is a safe and secure remote solution, for the diagnosis and recommendation of plastic solutions, by our experienced Technical Service staff, utilizing the latest in telecommunication technology.

Contact Us, our experts are ready to assist with your challenging applications to help reduce downtime and enhance food safety.

![]()