Why Plastics and Composites for the Automotive Industry?

Plastics and Composites have been used extensively in the manufacturing process of automobiles and as components of vehicles for many years. The assembly of automobiles involves a wide range of automated equipment including robotics, a vast number and many types of conveyors along with other automated processes, as well as racking and storage systems used to store and transport auto panels and other critical vehicle components.

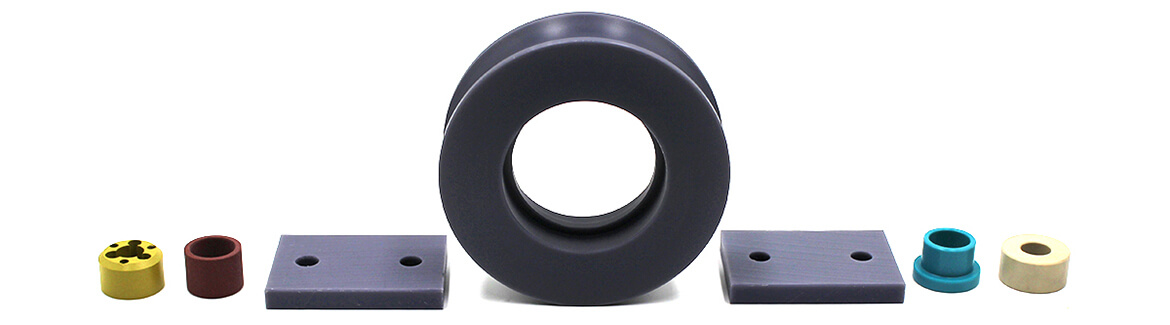

Many of the automated automotive processes benefit from the use of plastics and composites which offer a wide range of desirable material properties, some of which include: low friction, light weight, chemical and corrosion resistance, wear resistance, high impact strength, electrical insulation, antistatic and more. These properties offer benefits over traditional materials like aluminum, bronze and metal that result in reduced downtime and greater efficiencies in automobile production. In conveyor applications, antistatic plastics are used as automotive conveyor wear strips to help reduce wear on the conveyor system as well as eliminate static build up and unwanted static discharges, which protect workers and critical electronics. In many racking and storage systems, wear and impact resistant plastics are used to protect body panels and other critical vehicle components. Plastics and composites are used for a wide range of jigs and fixtures for wire harness assembly and many other areas to protect components. Plastics and composites comprise almost 10% of a new vehicle’s total materials by weight, which allows for lighter weight vehicles, enhanced electronics, improved chemical & corrosion resistance and more - which helps enhance vehicle performance, safety & longevity.

Why Boedeker Plastics, Inc. for the Automotive Industry?

Since 1984, we have worked closely with Engineering, Maintenance and Supply Chain personnel in all segments of the Automotive Industry to help reduce downtime and increase automotive manufacturing efficiency with our materials, parts and services.

Over the years, we have built a multimillion dollar inventory of high performance plastic and composite sheet, rod and tube and an ISO certified precision machine shop to support our clients with the most challenging requirements. We also offer injection molding with low cost modular tooling and specialize in insert and two shot molding. All inventoried materials are available with cut to size and same day shipping service.

For clients that have ongoing part requirements, we offer just-in-time (JIT) delivery with our customer inventory services. We also specialize in technical services that include material selection by application, improved part design assistance, onsite consultation and more. We stand ready to put our 500 years of combined experience and services to work for you.

As an alternative to onsite consultation we offer our TelePlastics™ remote support service. This is a safe and secure remote solution, for the diagnosis and recommendation of plastic solutions, by our experienced Technical Service staff, utilizing the latest in telecommunication technology.

Click here to view ALL AUTOMOTIVE INDUSTRY PLASTICS

![]()