Why Plastics and Composites for the Bulk Material Handling Industry?

The BMH (Bulk Material Handling) Industry utilizes hoppers, various types of conveyors, chutes, vibratory feeders, crushers and other BMH equipment to move and process a wide variety of bulk materials in many industries including: power generation, food processing, foundries, grain handling, and many others. Bulk materials such as coal, fertilizer, ore, gypsum, sand, cement, grains and countless more present challenges with abrasion, corrosion, static control and the flow of bulk materials which result in excessive downtime and lost production. Plastics and composites are often used to solve these common problems with BMH applications allowing for reduced downtime and more efficient plant operations.

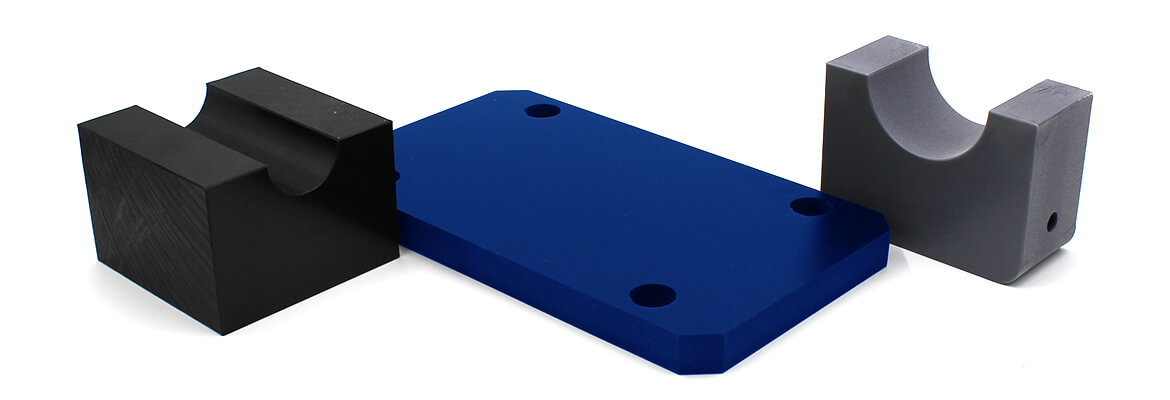

Materials such as TIVAR® 88 and other specialty lining plastics are utilized as linings in hoppers, bins and chutes to promote mass flow of sticky bulk materials, along with providing excellent abrasion and corrosion resistance. Composite bearings materials like CIP™ composites, Nylon and other plastics are utilized to replace bronze in bearing and wear applications to extend wear life with their self-lubricating, low friction and wear resistant properties to eliminate unwanted failures and downtime of bushings and bearings in conveyors, crushers, sliding gates, etc. Antistatic plastics are utilized as lining materials in grain handling chutes and other static-prone bulk materials to eliminate unwanted static build up and static discharge, greatly enhancing worker safety. Chemical and corrosion resistant plastics are used in a wide range of structural and bearing and wear applications to greatly extend part life.

Why Boedeker Plastics, Inc. for the Bulk Material Handling Industry?

Since 1984, we have worked closely with Equipment Engineers, Plant Engineers, Maintenance & Supply Chain personnel at BMH Equipment OEMs and at the plant level to help reduce downtime and increase mean time between repair for many BMH applications with our materials, parts & services.

Over the years, we have built a multimillion dollar inventory of high performance plastic and composite sheet, rod and tube and an ISO certified precision machine shop to support our clients with the most challenging requirements. All inventoried materials are available with cut to size and same day shipping service.

For clients that have ongoing part requirements we offer just-in-time (JIT) delivery with our customer inventory services. In addition, we offer injection molding for higher part volume requirements. We also specialize in technical services that include material selection by application, improved part design assistance, onsite consultation and more. We stand ready to put our 500 years of combined experience and services shop to work for you.

As an alternative to onsite consultation we offer our TelePlastics™ remote support service. This is a safe and secure remote solution, for the diagnosis and recommendation of plastic solutions, by our experienced Technical Service staff, utilizing the latest in telecommunication technology.

Click here to see ALL BULK MATERIAL HANDLING PLASTICS