Why Biodefense Plastics in critical applications?

Plastics play a critical role in Biodefense strategies and applications. With a wide range of properties available in key areas such as antimicrobial additives, sterilization (radiation, steam, etc.), high heat resistance, UV reflectivity and resistance, chemical resistance, biocompatibility, and structural strength, there is a plastic solution to almost every Biodefense challenge. Some

of the areas where plastics are being used in Biodefense are listed below along

with key Biodefense categories for common plastic materials in Biodefense

applications.

Biodefense Plastics By Category

Ultraviolet (UV) Germicidal Irradiation or UV Disinfecting Biodefense Plastics

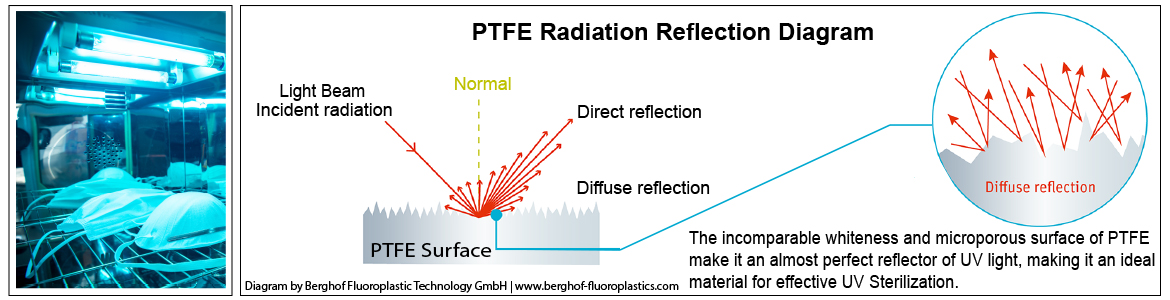

PolyTetraFluoroEthylene PTFE is inherently resistant to UV degradation and Highly Reflective to ultraviolet light, with reflectivity greater than 85% in the spectral range of 240-300 nanometers, up to 99% reflective in some cases. This makes PTFE an ideal choice for UVC light reflective barriers for Far UVC and Germicidal UVC disinfecting systems.

UV Light Reflectivity of Common Materials Used In Disinfection Reactors

Material

| Reflectivity |

| Stainless Steel (Various Grades) | 20 to 28% |

| Aluminium Foil | 73% |

| Aluminium Foil (Sputtered on Glass) | 80% |

| PolyTetraFluoroEthylene PTFE | 85 to 99% |

With the high purity of PTFE and ideal surface structure, a near-perfect Lambert’s reflection of reflectivity from 85 to 99% in a broad wavelength range of 250 to 2,500 nanometers is possible. This makes PTFE the material with the highest known diffuse reflection. Note: Special Optical grades of PTFE are also available that achieve a 99% reflection rate.

See the below diagram that demonstrates how light is reflected on the surface of PTFE.

Many UV disinfecting systems utilize UV resistant plastics for housings and other components that can withstand UV exposure. A few common UV resistant Polymers used in Biodefense applications include PVDF, Acrylic PMMA & Ultem PEI

Antimicrobial Biodefense Plastics

Antimicrobial additives are available for plastic materials. Many of these additives are silver based that can be compounded into the plastic to give the surface protection against stain and odor causing bacteria, algae and fungi. Note: These additives do not protect users or others against disease-causing bacteria and it is recommended to always clean thoroughly.

King MediGrade® Antimicrobial HDPE sheet is commercially available for a wide range of applications. Some of the common applications include housings for biodefense devices, cabinets, workstations components, wall coverings and more.

Biodefense equipment, Healthcare facilities, medical equipment and case goods made with King MediGrade® will stay cleaner and fresher between cleanings. Studies have shown that surfaces with the antimicrobial technology can inhibit the amount of certain product-damaging bacteria by 99.99%* compared to an untreated surface (See the chart below). The polymer sheet never needs painting or refinishing, works like wood and is easy to fabricate using common woodworking tools and techniques.

We also offer a wide range of injection molded material options with anti-microbial additives from commodity materials like HDPE, PP to high performance materials like Ultem and PEEK. Contact us for more information regarding your specific application.

Sterilizable Biodefense Plastics

Medical devices are sterilized in a variety of ways and many of those methods are used in biodefense sterilization applications as well. The housings and internal components of sterilization equipment are being made with a variety of plastics that can handle these sterilization methods.

Some of the most common methods of sterilization include steam, dry heat, radiation, ethylene oxide gas, vaporized hydrogen peroxide, and other sterilization methods (for example, chlorine dioxide gas, vaporized peracetic acid, and nitrogen dioxide).

Below is an example of a portable sterilization biodefense device being used to clean an office.

Some plastics perform well with these sterilization methods and others do not. Below is a chart that shows the most used plastics for sterilization applications such as device housings, autoclave cases/caddies/trays, critical components for handheld sterilization equipment and many other applications and devices for biodefense.

Sterilizable Biodefense Plastics by Sterilization Method

| Material | Ethylene Oxide Gas / ETO | Steam 121 C / 134 C | Dry Heat 160 C | Plasma | Gamma Radiation |

| PEEK | Excellent | Excellent | Excellent | Excellent | Excellent / Good - Grade Dependent |

| PPSU - Radel | Excellent | Excellent | Excellent | Excellent | Excellent |

| PEI - Ultem | Good | Good | Excellent | Good | Good |

| PSU | Good | Excellent | Good | Good | Good |

| PC | Good | Poor | Good / Not Suited -Grade Dependent | Good | Good / Poor - Grade Dependent |

| Acetal POM-C | Good | Poor | Not Suited | Good | Good |

| PC / ABS Blend | Good | Not Suited | Not Suited | Not Suited | Grade Dependent |

| PolyPro Heat Stabilized - Tecapro MT - Propylux HS2 | Excellent | Excellent | Not Suited | Good | Poor / Not Suited |

Boedeker Plastics, Inc & Biodefense Plastics

Over the years, we have built a multimillion dollar inventory which includes a wide range of commercially available Biodefense plastics and high performance biocompatible medical grade plastic and composite sheet, rod and tube, many which are FDA, USP Class VI, & ISO 10993 compliant plastics and an ISO certified precision machine to support our clients with the most challenging requirements for plastics only machined plastic and composite parts. Our entire inventory is coded for full traceability to give our customers peace of mind that they have received what they ordered. In addition, we offer injection molding for higher part volume requirements in applications that require medical grade molded parts. All inventoried materials are available with cut to size and same day shipping service. For clients that have ongoing part requirements, we offer just-in-time (JIT) delivery with our customer inventory services.

We have a variety of secondary manufacturing processes that allow us to manufacture a complete medical part solution that meets the unique regulatory and application requirements of the medical industry and biodefense applications. Some of these processes include assembly, laser marking, UDI laser marking, annealing, cryogenic deburr technology along with other processes.

We also specialize in technical services that include material selection by application, improved part design assistance, onsite consultation and more. We stand ready to put our 500 years of combined experience and services to work for you.

As an alternative to onsite consultation we offer our TelePlastics™ remote support service. This is a safe and secure remote solution, for the diagnosis and recommendation of plastic solutions, by our experienced Technical Service staff, utilizing the latest in telecommunication technology.

![]()