Be our guest at AeroDef 2020

AERODEF 2020 HAS BEEN POSTPONED

SME is announcing that given the escalating concerns around COVID-19, we have made the difficult decision to postpone AeroDef 2020 scheduled for March 16-19 in Fort Worth, Texas.

EXPLORE NEW HORIZONS AT AERODEF 2020

We’re Exhibiting at AeroDef 2020! Booth 415

Fort Worth Convention Center, Fort Worth, Texas

Exhibit Hall - Tuesday, March 17, 2020 | 10:00 AM – 5:30 PM

Exhibit Hall - Wednesday, March 18, 2020 | 10:00 AM – 5:30 PM

Be Our Guest

Register for Your Free Exhibit Hall Pass

Why Attend AeroDef Manufacturing 2020?

Get easy access to the smart technologies and intelligent people propelling aerospace and defense manufacturing at AeroDef 2020, March 16-19 in Fort Worth, Texas. See what’s coming and what leading companies are doing to stay competitive at the industry’s premier conference and exposition, where you’ll find integrated technology solutions from more than 200 aerospace and defense manufacturing suppliers, including aerospace manufacturing, defense manufacturing, composite manufacturing, and more. You’ll also find innovative manufacturing processes and high-end educational conference sessions that can help make your business vision a reality.

What Past Attendees Say:

"AeroDef provides an opportunity to hear OEM's and manufacturers' future needs and technology strategies."

"I liked how there was a diverse range of industries, technologies, and professionals that were present during this event. I feel everything about it was interesting and fun.

Why Visit Boedeker Plastics, Inc. And Mitsubishi Chemical Advanced Materials at AeroDef 2020?

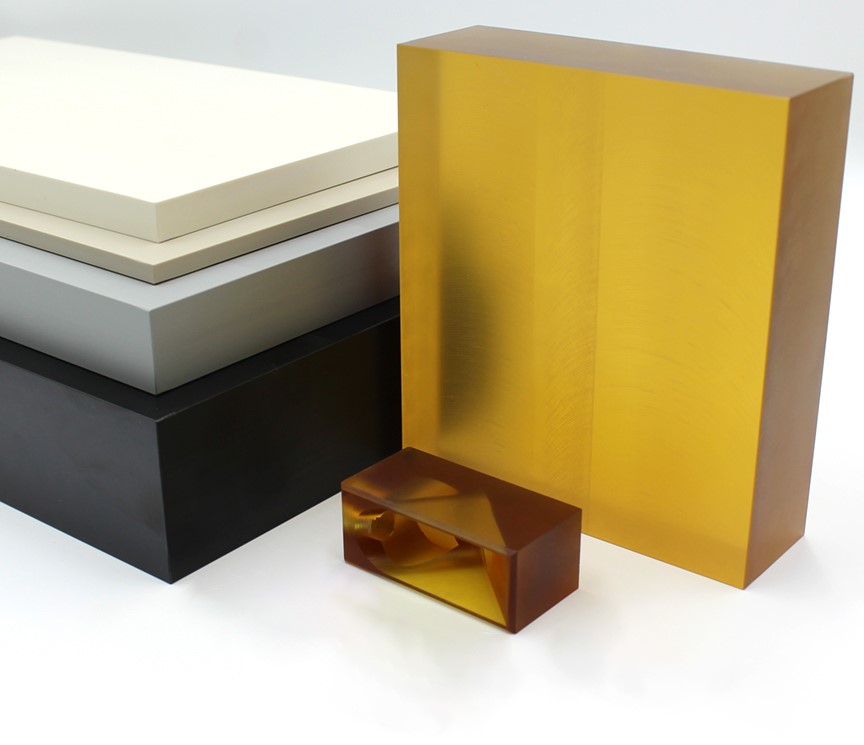

Boedeker Plastics, Inc. (BPI) and Mitsubishi Chemical Advanced Materials (MCAM) are teaming up to bring the latest Advanced Engineering Thermoplastic innovations to attendees this year, at AeroDef 2020. We will be showcasing the latest advanced engineering thermoplastic sheet, rod and tube, precision machined and injection molded parts for Interior, System, Structure & Propulsion applications in the Aerospace Industry.

Technical staff from Boedeker & Mitsubishi Chemical Advanced Materials will be on hand to help with material selection by application from Mitsubishi Chemical Advanced Materials’ product portfolio, backed by Boedeker’s unmatched plastic and composite inventory and service with JIT supply programs, plastics only precision machining and injection molding for high part volume applications. Our technical experts are eager to help you select the best turnkey package for your challenges.

What Past Attendees Say:

"AeroDef provides an opportunity to hear OEM's and manufacturers' future needs and technology strategies."

"I liked how there was a diverse range of industries, technologies, and professionals that were present during this event. I feel everything about it was interesting and fun.

Why Advanced Engineering Plastics for Aerospace Applications?

Advanced engineering plastics are widely used for improved efficiency and reliability in Interior, System, Structure and Propulsion applications in the Aerospace Industry. These materials offer weight reduction that increases fuel efficiency and lowers greenhouse gas emissions. Additional properties include high strength to weight ratio, resistance to industrial chemicals, electrical and thermal insulation, low friction, temperature performance across a wide range from low to high temperature, and excellent wear resistance. In addition, we have a line that offers ESd and conductive properties.

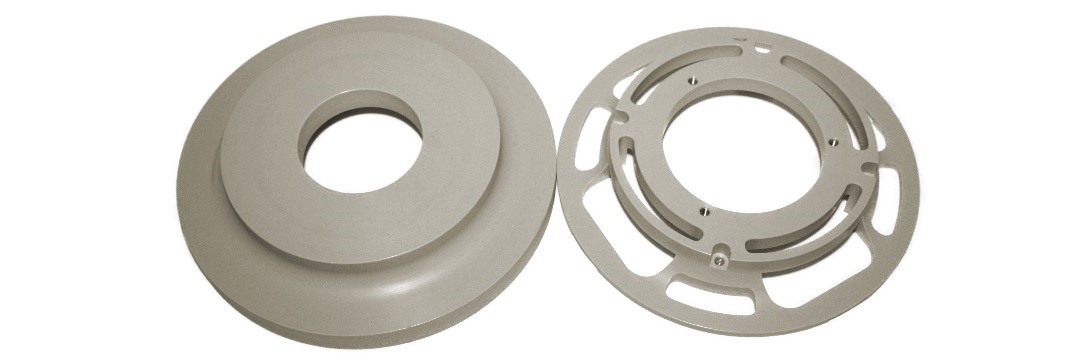

Reduce Plastic Part Manufacturing Costs with Near Net Shape (NNS) Molding Technology

Aerospace Engineers have a new option for cost reduction and broader material selection for plastic parts with NNS Technology. Often, machineable stock shapes are not available in the resin you need or the configuration to meet your requirements.

The KETRON PEEK bracket shown required tight tolerances. Machining from standard plate required numerous steps resulting in additional machining time and costly material waste. In this application NNS technology was used to supply a near-net shape, greatly reducing manufacturing costs. NNS Technology is available from Boedeker in partnership with Mitsubishi Chemical Advanced Materials.

Learn More About Aerospace Industry Plastics & Applications Here

For more Information on AeroDef Visit https://aerodefevent.com/

Be Our Guest - Register for Your Free Exhibit Hall Pass

2886