ULTEM ™ PEI Key Properties

ULTEM™ offers excellent dimensional stability combined with broad chemical resistance. ULTEM™ is also inherently flame resistant and low smoke generating. It excels in medical reusable applications requiring repeated sterilization and is available in FDA compliant colors.

- Capable of Withstanding Multiple Autoclaving Cycles

| - High Continuous Use Temp of 340F

| |

- High Heat Deflection Temperature

| | - Inherently Flame Retardant – UL 94 V-0 Rated

|

| | |

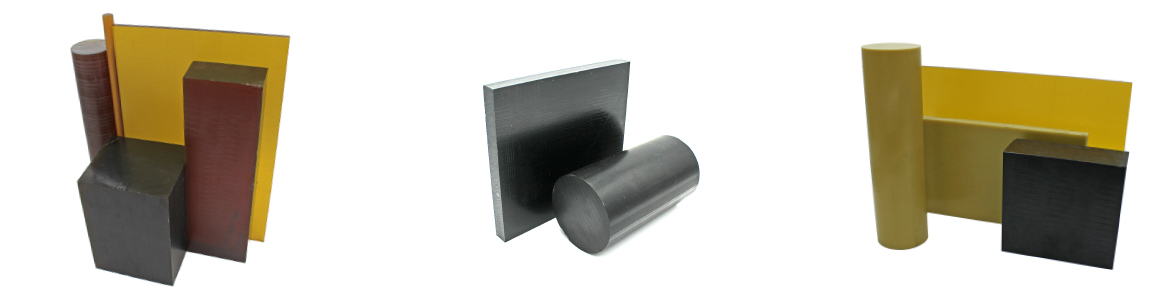

Available ULTEM ™ Grades

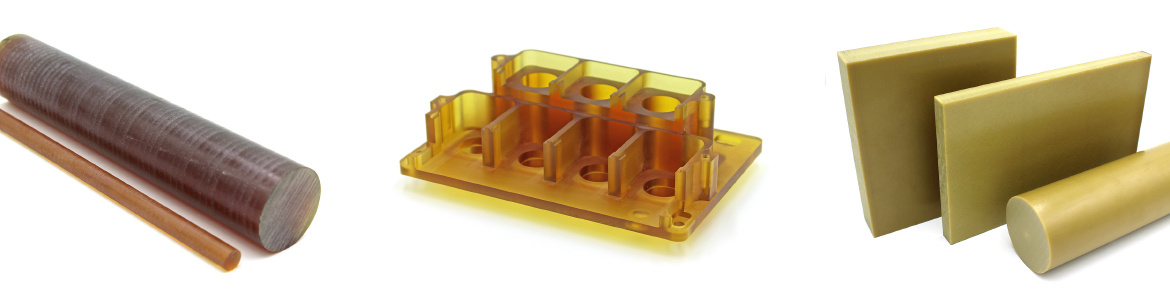

| ULTEM™ 1000 - is an amber transparent high-performance unfiled PEI polymer which combines high strength and rigidity at elevated temperatures with long term heat resistance. ULTEM™ 1000 offers excellent dimensional stability combined with broad chemical resistance. We offer ULTEM™ 1000 for Online Purchase in sheet and rod. | ULTEM™ 2100 - is a 10% glass filled PEI grade with improved rigidity and stiffness. This grade is less common and may require minimum runs and longer lead times. |

ULTEM™ 2200 - is a 20% glass filled grade of PEI. This grade is less common and may require minimum runs and longer lead times.

| ULTEM™ 2300 - is a 30% glass filled grade with improved strength and stiffness. ULTEM™ 2300 is the most common filled ULTEM™ and is readily available from stock in sheet and rod forms. We offer ULTEM™ 2300 for online purchase in sheet or rod. |

| Static Dissipative & Conductive PEI Grades - We offer a variety of PEI Grades formulated with static dissipative and conductive electrical properties for critical electrical and semiconductor applications. We stock the entire line of Semitron PEI grades. | Other Trade Names - Other PEI products are available as follows by the following trade names, Duratron U Series, SustaPEI, TECAPEI, ZL 1000 |

ULTEM ™ HU1000 PEI Medical Grade - We offer ULTEM™ 1000 made from HU1000 resin for medical applications. If you require ULTEM™ made from HU1000 PEI medical grade resin it must be specified at the time of order. HU1000 is ECO Conforming and is formulated for for medical devices and pharmaceutical applications. It offers biocompatible (ISO 10993 or USP Class VI); food contact compliant; Steam, Gamma, EtO, and E-beam sterilizable.

![]()

Boedeker Plastics, Inc. & ULTEM ™ PEI

We

stock all commercially available grades of ULTEM™ PEI sheet, rod, tube and film

and offer cut to size, same day shipping on all inventoried ULTEM™

PEI materials.

Our entire inventory of ULTEM™ PEI is coded for full traceability,

we offer manufacturer certs. and C of C’s upon request at the time of order for

all orders.

We

specialize in plastics-only machining, including ULTEM™ PEI machining and

produce CNC machined ULTEM™ PEI parts for prototype to

production quantities.

In

addition, we offer injection

molding for

higher part volume requirements in application that require ULTEM™ PEI molded parts. For clients that

have ongoing part requirements, we offer just-in-time (JIT) delivery with our customer inventory services.

We also specialize in technical

services for

ULTEM™ PEI materials and parts that include material selection by application,

improved part design assistance, onsite consultation and more.

As an alternative to onsite consultation

we offer our TelePlastics™ remote

support service. This is

a safe and secure remote solution, for the diagnosis and recommendation of

plastic solutions, by our experienced Technical Service staff, utilizing the

latest in telecommunication technology.

We stand ready to put our 1,800 years of combined experience and services to work for you.

![]()