What is Static Electricity?

It’s what the name implies -- electricity at rest. This electrical charge is the result of a transfer of electrons that occurs due to the sliding, rubbing, or separating of a material, which is a prime generator of electrostatic voltages -- e.g.: plastics, fiber glass, rubber, textiles, etc. Under the right conditions, this induced charge can build to 30,000 or 40,000 volts. When this happens to an insulating material, such as a plastic, the built-up charge tends to remain in the localized area of contact. This electrostatic voltage then can discharge via an arc or spark when the plastic material comes in contact with a body at a sufficiently different potential, such as a person or microcircuit.

Why is it important to control electrostatic discharge?

If electrostatic discharge (ESD) occurs to a person, the result can range anywhere from a mild to a painful shock. In extreme cases, ESD could even result in loss of life. Sparks are dangerous in an environment containing flammable liquids, solids or gases, such as in a hospital operating room or during the assembly of explosive devices.

Some micro-electronic parts can be destroyed or damaged by ESD as low as 20 volts. Since people are prime causes of ESD, they often cause damage to sensitive electronic parts, especially during manufacturing and assembly. The consequences of discharge through an electrical component sensitive to ESD can range from erroneous readings to permanent damage resulting in excessive equipment downtime and costly repair or total part replacement.

How are materials measured for static discharge?

Surface Resistivity - For thermoplastic materials intended to dissipate electrostatic charges, surface resistivity is the most common measurement of a material’s ability to do so.

ASTM D257 Standard Test Methods for DC Resistance or Conductance

of Insulating Materials - includes a widely accepted surface resistivity test method for surface resistivity. It consists of measuring the resistance (via an ohm meter) between two electrodes applied under load to the surface being tested. It is important that Electrodes are used rather than point probes because of the heterogeneous makeup of compounded thermoplastics. Simply touching the surface with a point contact may not give readings consistent with the overall part (readings of this type are often insulative even when the part is actually conductive). These test methods are not suitable for use in measuring the electrical resistance/conductance of moderately conductive materials.

EOS/ESD S 11.11 Surface Resistivity Testing - is another test that measures the ability of electric current to flow over the surface of a material and is expressed in ohms/square area. This procedure is recommended by EOS/ESD Association,

Inc. instead of ASTM D257 for measuring the surface resistance of static

dissipative planar materials. The test electrodes measure area-to-area and

are both placed on the same side of the test specimen. To measure current flow,

one must consider that the surface resistivity may be affected by environmental

changes such as moisture absorption. The more readily the current flows,

the lower the surface resistivity.

It is also important to maintain good contact between the sample and electrodes, which can require considerable pressure. The resistance reading is then converted to resistivity to account for the dimensions of the electrodes which can vary depending on the size and shape of the test samples. Surface resistivity is equal to resistance times the perimeter of the electrodes divided by the gap distance, yielding ohms/square.

Surface resistivity is used to evaluate and select materials for testing when static charge dissipation or other surface characteristics are critical. Contact Us for regarding your specific application, our Technical Staff stands by to assist with your application and technical questions.

Volume Resistivity -Volume resistivity, also called bulk resistivity is useful for evaluating the relative dispersion of a conductive additive throughout the polymer matrix. It can roughly be related to EMI/RFI shielding effectiveness in certain conductive fillers. Volume resistivity is tested in a similar fashion to surface resistivity, however electrodes are placed on opposite faces of a test sample. ASTM D257 also refers to volume resistivity, and a conversion factor again based on electrode dimensions and part thickness is used to obtain the resistivity value from a resistance reading. [Volume resistivity is equal to resistance times the surface area (cm2) divided by the thickness of the part (cm) yielding ohm-cm.]

![]()

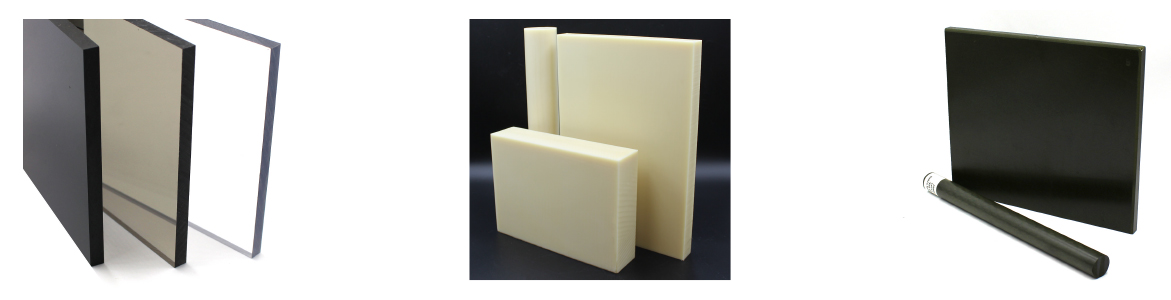

Boedeker Plastics, Inc & Static Control Plastics

We stock all commercial available grades of Static Control ESD Plastics and offer cut to size, same day shipping on all inventoried Static Control materials. Our entire inventory of Static Control ESD Plastics is coded for full traceability, we offer manufacturer certs. and C of C’s upon request at the time of order for all orders.

We specialize in plastics-only machining, including Static Control ESD Plastics machining and produce CNC machined Static Control ESD Plastics parts for prototype to production quantities.

In addition, we offer injection molding for Static Control ESD Plastics Parts for higher part volume requirements.

For clients that have ongoing part requirements, we offer just-in-time (JIT) delivery with our customer inventory services.

We also specialize in technical services for Static Control ESD Plastics and parts including: material selection by application, part design assistance & machining support, onsite consultation and more.

As an alternative to onsite consultation we offer our TelePlastics™ remote support service. This is a safe and secure remote solution, for the diagnosis and recommendation of plastic solutions, by our experienced Technical Service staff, utilizing the latest in telecommunication technology.

We stand ready to put our 1,800 years of combined experience and services to work for you.

![]()