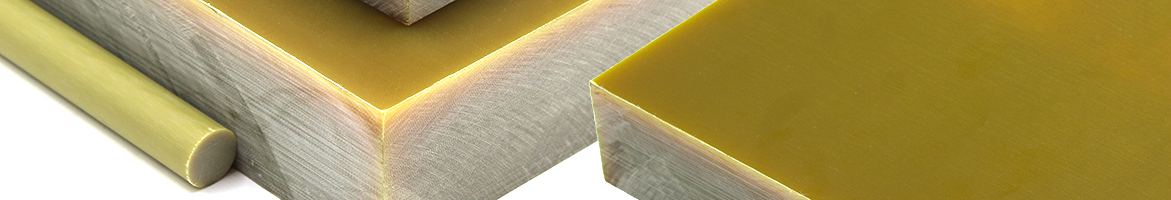

Glass Filled Industrial Laminate Grades

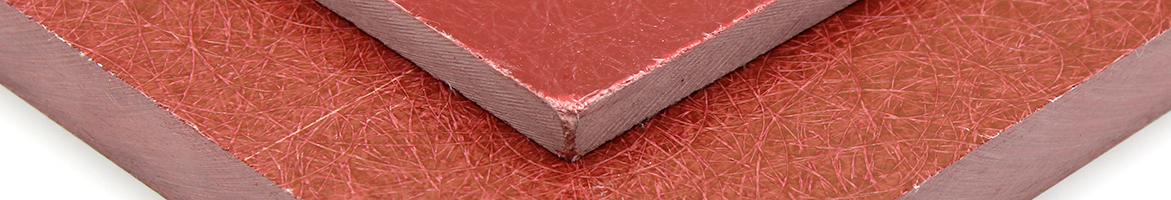

GPO-3 (Glass / Polyester Resin)

- GPO-3 is a rigid fiberglass reinforced composite laminate with a polyester resin system, it is flame retardant and is used for general purpose electrical and/or mechanical applications where low cost is desired. GPO-3 can withstand higher temperatures compared to GPO-1 or GPO-2 grades and exhibits better electrical characteristics. GPO-3 offers excellent dimensional strength, high impact strength, high strength, excellent electrical properties and good flame and smoke characteristics. For complete data on all standard available GPO Grades including GPO-1, GPO-2, GPO-3 and Specialty Grades DOWNLOAD OUR COMPLETE GPO GRADES DATA SHEET COMPARISON

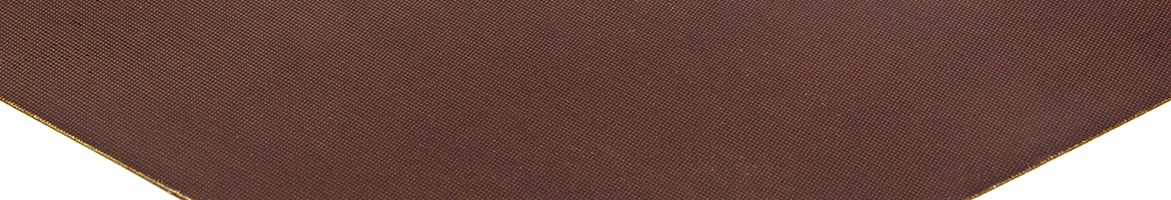

G-3 (Glass Cloth / Phenolic Resin)

- This material is made from woven glass cloth and high-temperature phenolic resin. It has excellent flexural, compressive and impact strengths and is capable of continuous operation over 350°F (175°C). NOTE: G-3 is not a common material. Contact Us for more information about availability.

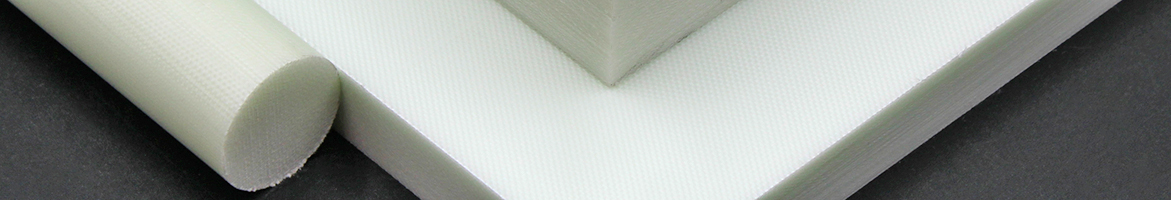

G-5 and G-9 (Glass Cloth / Melamine Resin)

- These materials are very hard, flame resistant, and have excellent electrical properties. G-5 and G-9 have high arc and heat resistance. G-9 is recommended for humid environments. They are used for switch board panels, arc barriers, circuit breaker parts, and structural electrical parts Melamine phenolics are available in sheet, rod, and tube forms.

G-7 (Glass Cloth / Silicone Resin)

- This glass-silicone laminate has good electrical properties under humid conditions, excellent heat and arc resistance, and is self-extinguishing. G-7 is used for electrical grade insulation, and for heating & appliance insulation.

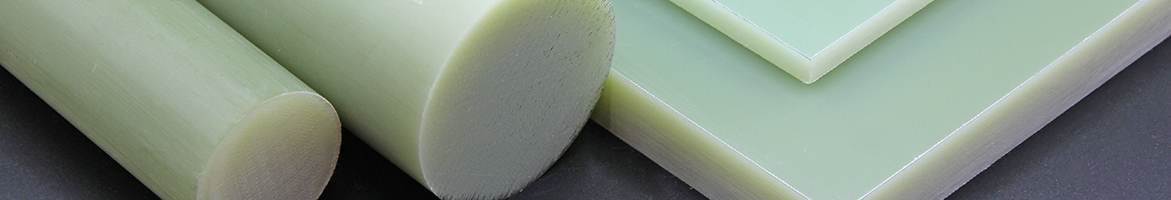

G-10 and G-10 FR-4 (Glass Cloth / Epoxy Resin)

- These glass-epoxy laminates are specified for their extremely high strength and high dimensional stability over temperature. G-10 is used for terminal boards, high humidity applications, electrical and electronic test equipment and electric rotor insulation. G-10 is difficult to cut or machine and may require special equipment. G-10 is slightly stronger than G-11, but is a better insulator and can take higher temperatures. G-10 FR-4 is a fire-retardant G-10 glass-epoxy laminate that is used primarily in the printed circuit board industry.

G-11 and G-11 FR-5 (Glass & Higher Temp Epoxy Resin)

- A grade similar in composition and properties to Grade G-10 but more suitable for continuous use at elevated temperature. G-11 retains at least 50% of its structural strength at continuous operating temperatures in excess of 300°F. "FR" grades are flame retardant.

Military & Federal Specifications of Glass Laminates GPO-3, G-3, G-7, G-9, G-10 / FR-R, G-11

*If you require certification to a MIL Spec it must be requested at the time of order.

Common Glass Filled Industrial Laminate Applications

| - Downhole Oil & Gas Components

| - Electrical Housings & Connectors

|

| - High Strength Structural Components

| |

- Frac Balls & Bridge Plugs

| - Insulative Jigs & Fixtures

| |

Chemical Resistance of Glass Based Industrial Laminates (G-3, G-9, G-10 FR-4 & G-11)

In general glass based industrial laminates offer excellent chemical resistance and will vary depending on resin system. For additional information on specific grades and chemicals, Download Our Industrial Laminate (G-3, G-9, G-10 FR-4, G-11) Chemical Resistance Guide If you require further assistance with a specific chemical or application specifics contact us, our Technical Staff stands ready to assist.

![]()

Boedeker Plastics, Inc. & Glass Filled Industrial Laminates

We stock a wide range of commercially available GPO 1, GPO 3, G 3, G 5, G 7, G 9,

G 10 & G 11 Glass Laminate Composite grades in sheet, rod & tube and

offer cut to size, same day shipping on all inventoried materials. Our entire

inventory of GPO 1, GPO 3, G-3, G-5, G-7, G-9, G-10 & G-11 Glass Laminate Composites is coded for full traceability, we offer manufacturer certs. and C of C’s

upon request at the time of order for all orders.

We specialize in plastics-only machining and produce CNC machined GPO 1, GPO 3, G3, G5, G7, G9, G10 & G11 Glass Laminateparts for prototype to production

quantities.

We also specialize in technical services for GPO 1, GPO 3, G3, G5, G7, G9, G10 & G11 Glass Laminates and parts including: material selection by application, part design assistance & machining support, onsite consultation and more.

As an alternative to onsite consultation we offer our TelePlastics™ remote support service. This is a safe and secure remote solution, for the diagnosis and recommendation of plastic solutions, by our experienced Technical Service staff, utilizing the latest in telecommunication technology.

We stand ready to put our 1,800 years of combined experience and services to work for you.

![]()